Semi | Fire extinguisher for high-way transport truck drivers

Semi is a fire extinguisher specifically designed for extinguishing mild engine fire from high-way transport trucks. The main objective of this project was to identify needs through general research and identify problems + solutions through well planned user testing.

Research

Transport trucks occupy about 9% of all fires reported from highway vehicles. Fires are most likely to originate from (1) engine, running gear, wheel area and (2) operator/ passenger area. Engine fire has to be extinguished through louvers/radiator or from the underside of the vehicle; reaching over and under the large vehicle like a transport truck is very difficult.

In general, trucks that are 4 to 5 years old have the highest incidence involving fires. This is because trucks that are 4 to 5 years old start to cause mechanical problems; newer trucks are safer because they come with better technologies and safety related sensors. Also, younger drivers are more likely to be involved in fire incidents compared to older drivers. Younger drivers are usually less careful and have less experience. Furthermore, truck fires are more likely to occur within the first 100 days following a crash.

Procedure for Extinguishing Truck Engine Fire

1) Park in an open area, away from buildings, trees, bushes, other vehicles or anything that might catch fire.

2) With an engine fire, turn off the engine as soon as possible.

3) Get off the vehicle (do not open the hood of the vehicle).

4) Grab the fire extinguisher and follow the instructions on the fire extinguisher (fire extinguisher is usually located near the driver’s seat).

5) Release the extinguisher through the louver, radiator, or from underneath the vehicle.

Design Brief

The objective of this project is to design a fire extinguisher that is well suited for highway transport truck drivers. There are multiple things to consider in designing a fire extinguisher for highway transport truck drivers because trucks are not just for transportation; they are also a home and office during their journey from point A to point B.

The extinguisher should be easy to carry from interior to exterior or vice versa, as fires can occur in either the interior or exterior. Also, the extinguisher should be securely mounted while the truck is being driven to prevent the extinguisher from being the cause of the accident. Furthermore, the truck driver must be able to reach both high and low ground with the nozzle of the fire extinguisher.

The fire extinguisher will be targeted towards drivers around the age of 25 to 35 who drive transport trucks that are between 3 to 7 years old.

Images from Volvo Trucks

Initial Ideation

After a thorough research on fire extinguisher and semi truck environment, components such as handle orientation, safety pin mechanism, operation mechanism, nozzle types and form of the body was the main focus of the initial ideation.

Prototypes

1. Fire extinguisher with a short nozzle that rotates to help the user extinguish fire in comfortable posture.

2. Fire extinguisher with extendable nozzle similar to traditional fire hose.

A. Gun type nozzle handle

B. Flat type nozzle handle

C. Walkie Talkie type nozzle handle

User Testing Setting

A large truck (not exactly a life size) was sketched onto the wall using thin black masking tape. This was done To show the relative size of a highway transport truck. Also, to give participants something to aim at, paper fire was attached to the engine area.

Purpose of this user testing was to figure out whether users feel more comfortable using the fire extinguisher with a longer hose or the fire extinguisher with a shorter nozzle (adjustable handle). Testing was also performed to find out which nozzle type was most comfortable for switching between different positions when using the fire extinguisher with a long hose

observation

Lots of insight was gained through user testing. Participants gave feedback on which mechanism (long hose vs. short nozzle) was easier to use for different positions. Majority of the participants chose the prototype with the hose; many participants did not know how to use the one without the hose. Furthermore, The prototype with the hose had three different nozzle types. Participants pointed out which handle(s) worked the best for different positions.

findings

Despite all the great information, the most important insight was drawn from the unexpected result from the testing. Almost all of the participants went down on their knees when they were pretending to extinguish the fire from the underside of the vehicle. This posture is very dangerous as users of fire extinguishers should be ready to evacuate fast at all times.

Nest Step

Keeping the users standing up while using the fire extinguisher is the new consideration gained from the testing stage.

Improvement 1 | Affordance

Make it easier for the users to understand that the fire extinguisher’s hose is expandable / retractable.

Improvement 2 | Affordance

Make it easier for the users to understand that the nozzle has to be pulled out.

Improvement 3 | Internal Component

Separate the reel area with compressed gas cartridge area.

Inspiration

Highway transport trucks are not just transportation for the drivers. Trucks are also a small cozy home for the drivers during the break time. In order to keep drivers' small space feel like home, forms for the fire extinguisher were inspired by forms and components of household products.

Use Cycle

Until step 4, the user follows the same procedure as mentioned in the Research section.

5) Pull the safety pin to puncture the internal gas cartridge.

6) Extend the nozzle to a comfortable length.

7) Release the extinguisher through the louver, radiator, or from underside of the vehicle.

Safety pin facing the back instead of the left or right makes it easier for both left and right handed users to pull the pin. Also, the handheld nozzle allows users to reach the underside of the vehicle without going down on their knees (which was the major problem found during the User Testing).

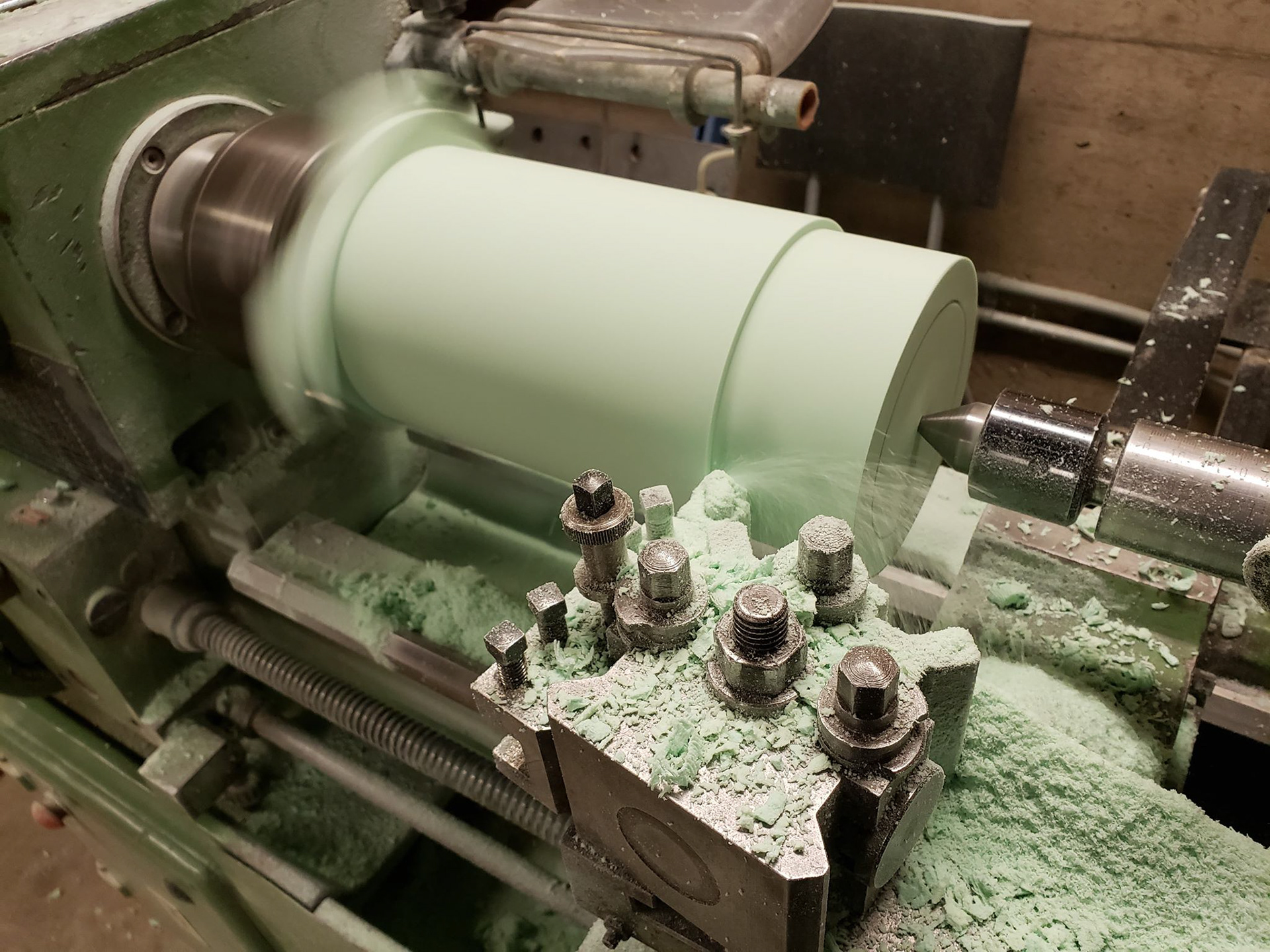

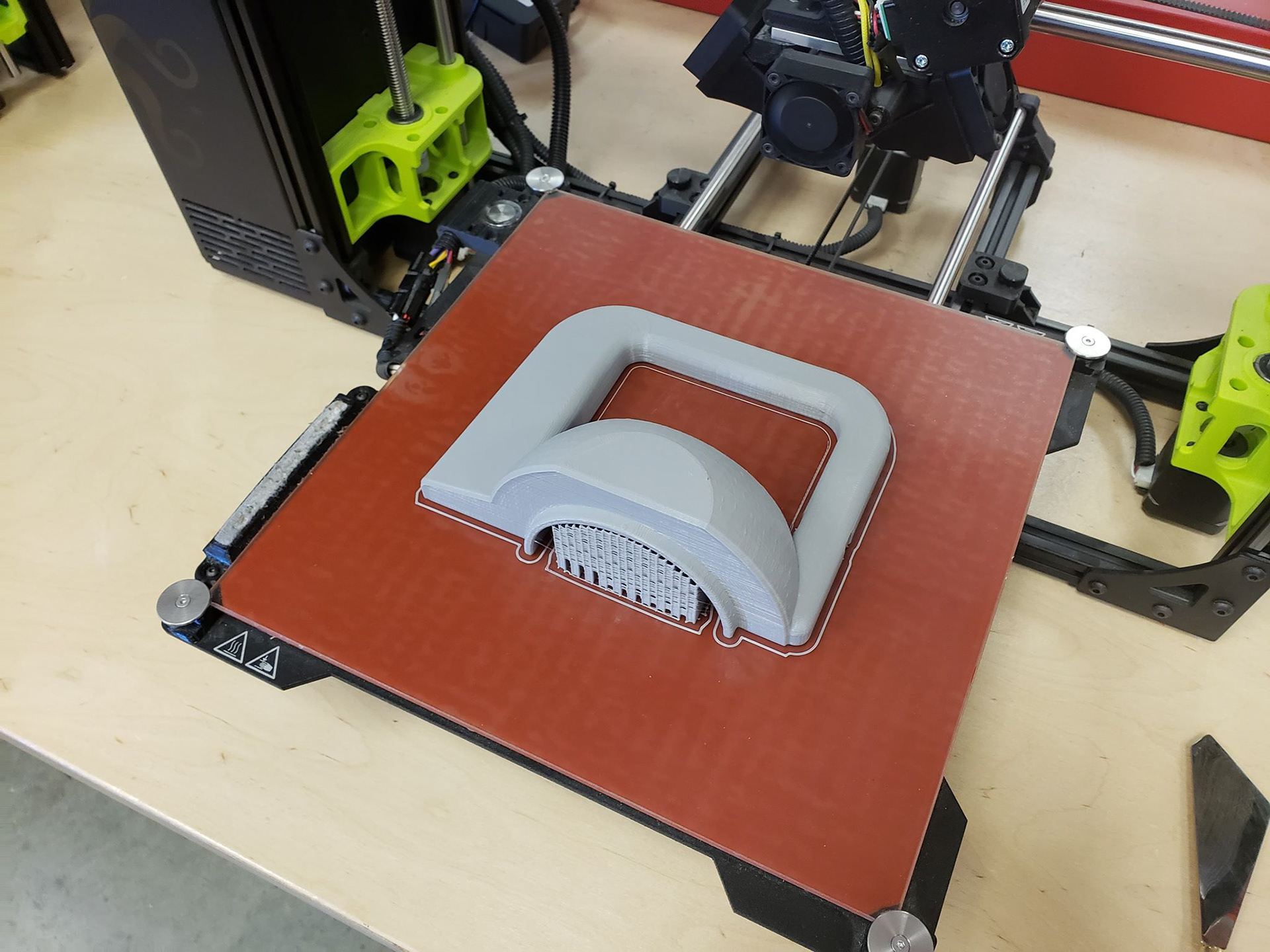

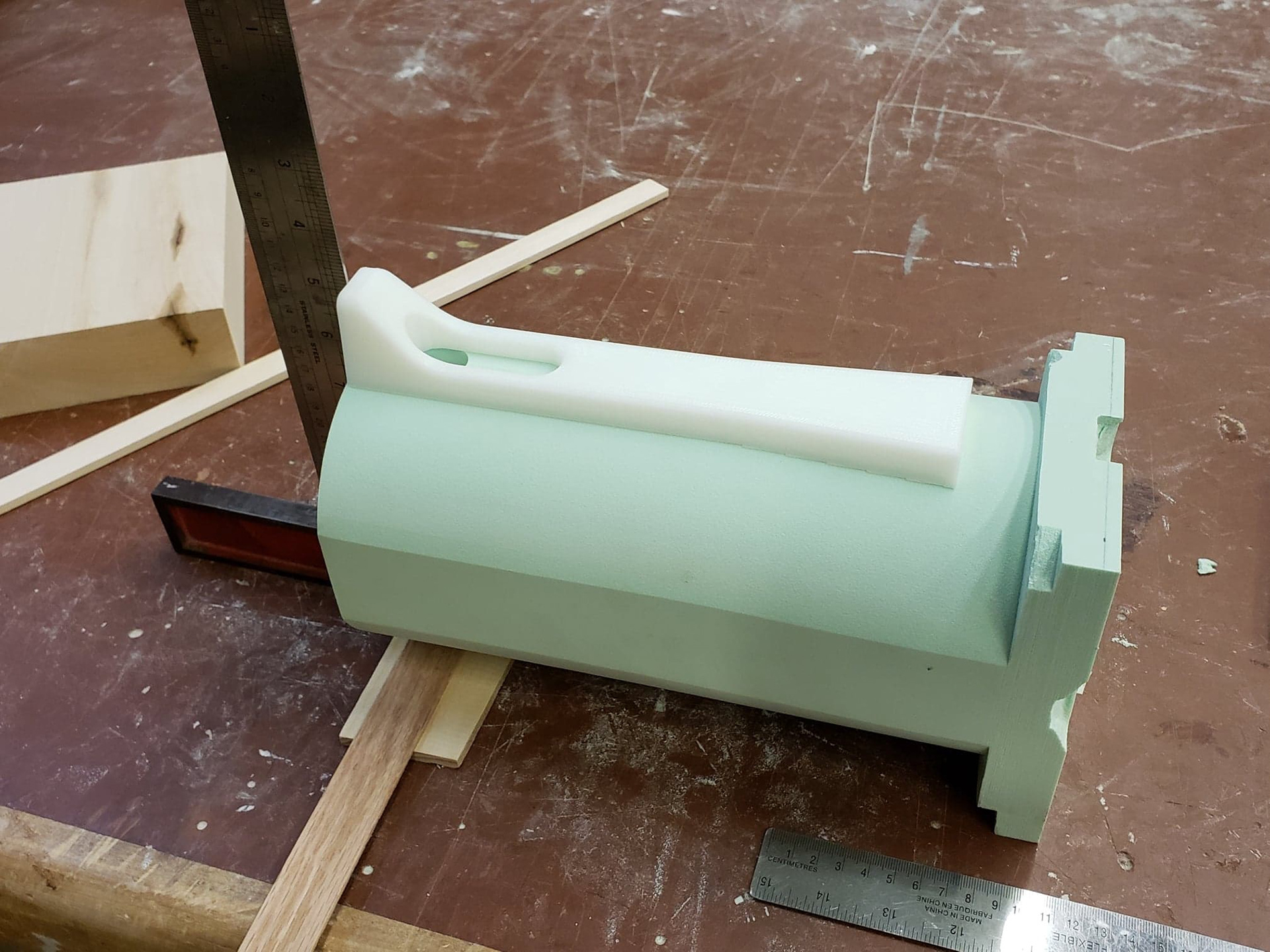

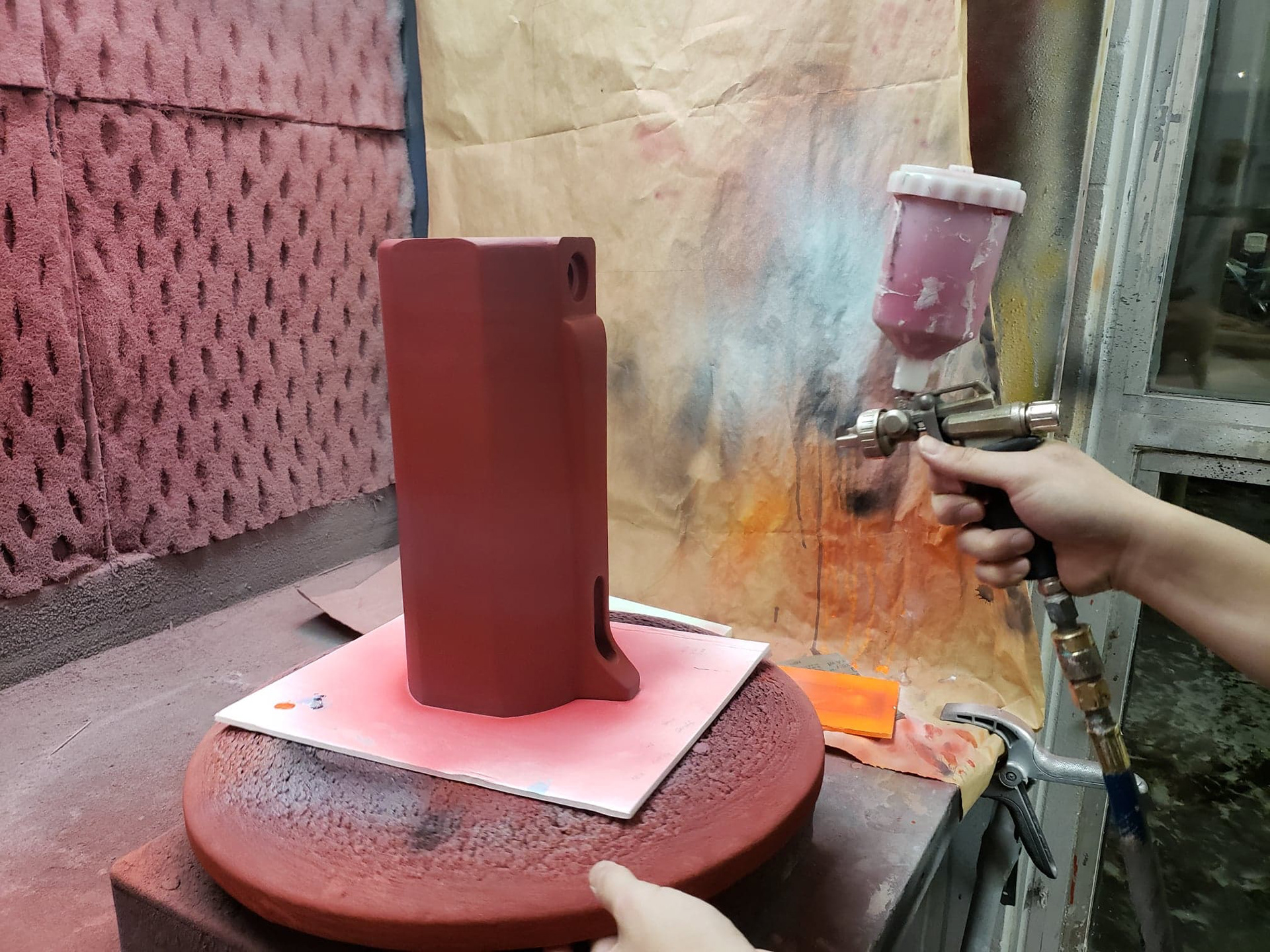

Model Making

Final model made with machined high density foam and 3D printed PLA parts. Coats of drydex were applied to rough surfaces and polished with wet sandpapers. Two coats of paint were applied at the end to complete the model.

Final Model

General foundation of the design is similar to the extendable hose prototype from the initial design phase. Final design has a more ergonomic nozzle and takes design cues from soft household products.

Thank you very much for reading

SEMI focuses on the user's posture for extinguishing engine fire for the transport trucks. There are many components that have not been looked at in detail such as mounting system, pressure gauge, instruction, and maintenance etc.

Next step for this project is to diverge into broads topic of the fire extinguisher for the highway transport truck drivers. After iterations and testing convergence will take place and set a new focus. This will then lead to new innovation that is different from the solution found through this project.